Renewed Barrels

Recovering the hidden value in your oak wine barrels. Rewine’s process is based on sound science: remove the layer of neutral oak from the interior of the barrel to expose new oak fibers, vaporize and extract the remaining polyphenols and release the oak compounds from the freshly exposed new fibers through thermal degradation allowing them to bond with wine chemicals.

how our process works

Our renovation process consists of 5 steps:

Mechanically removing about 5mm (3/16”) of wood from the inside of the barrel (including heads) using a proprietary shaving machine and hand tools. This removes the color, sugars and dissolved solids and exposes fresh wood fibers.

Thoroughly heating the barrels to a minimum of over 200F through out the staves (up to 380F in the interior) with electric convection elements to vaporize all remaining VOCs and any biologicals.

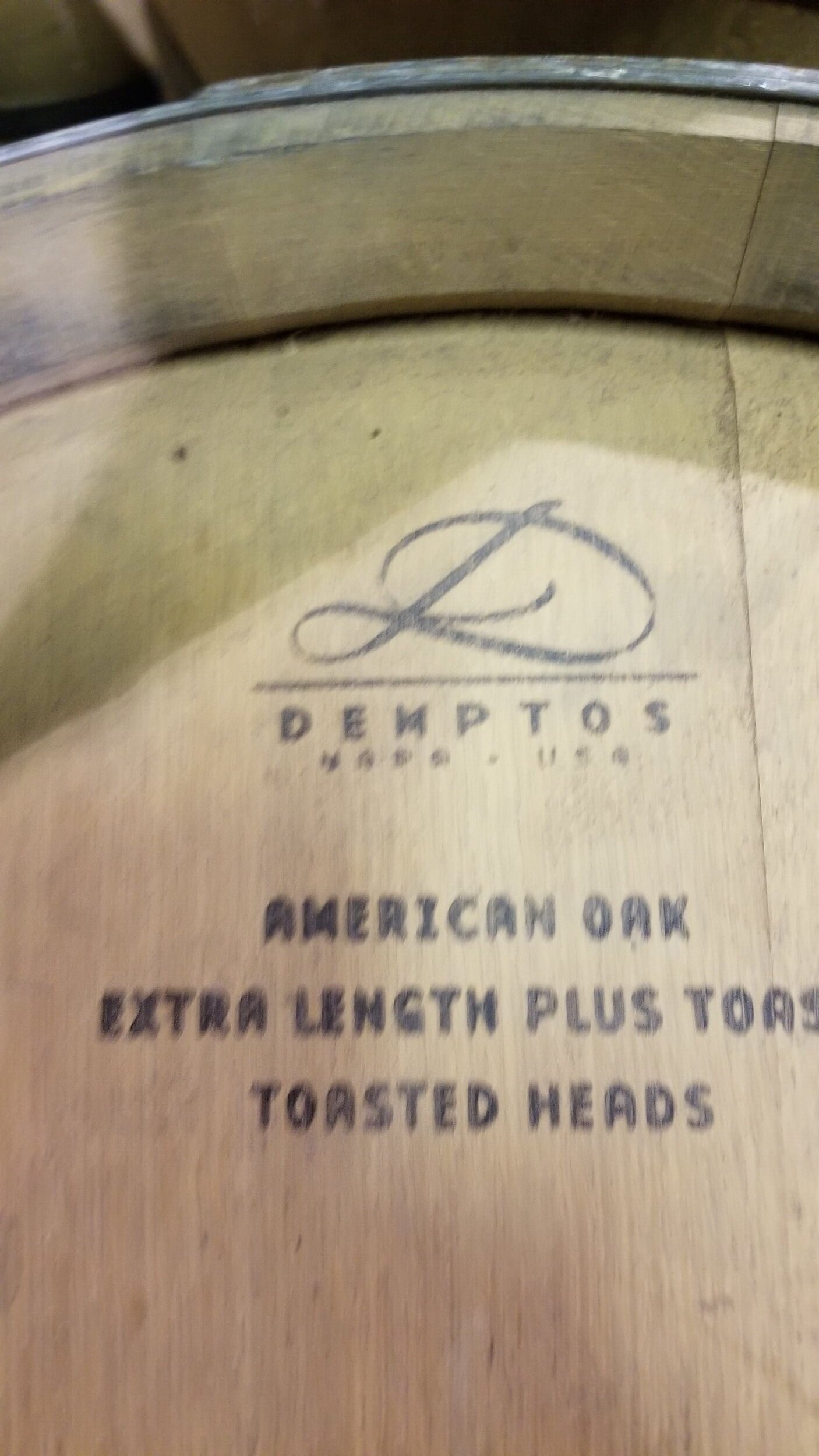

Toasting to the desired level - Light, Medium Light, Medium, Medium Plus or Heavy.

Re assembly of the barrels and hydration to insure water tightness.

SO2 gassing and plastic wrap. Barrels are hydrated and sterile and ready to be filled anytime within 4 to 6 weeks without rehydration.

Don’t have barrels? We’ve got you covered.

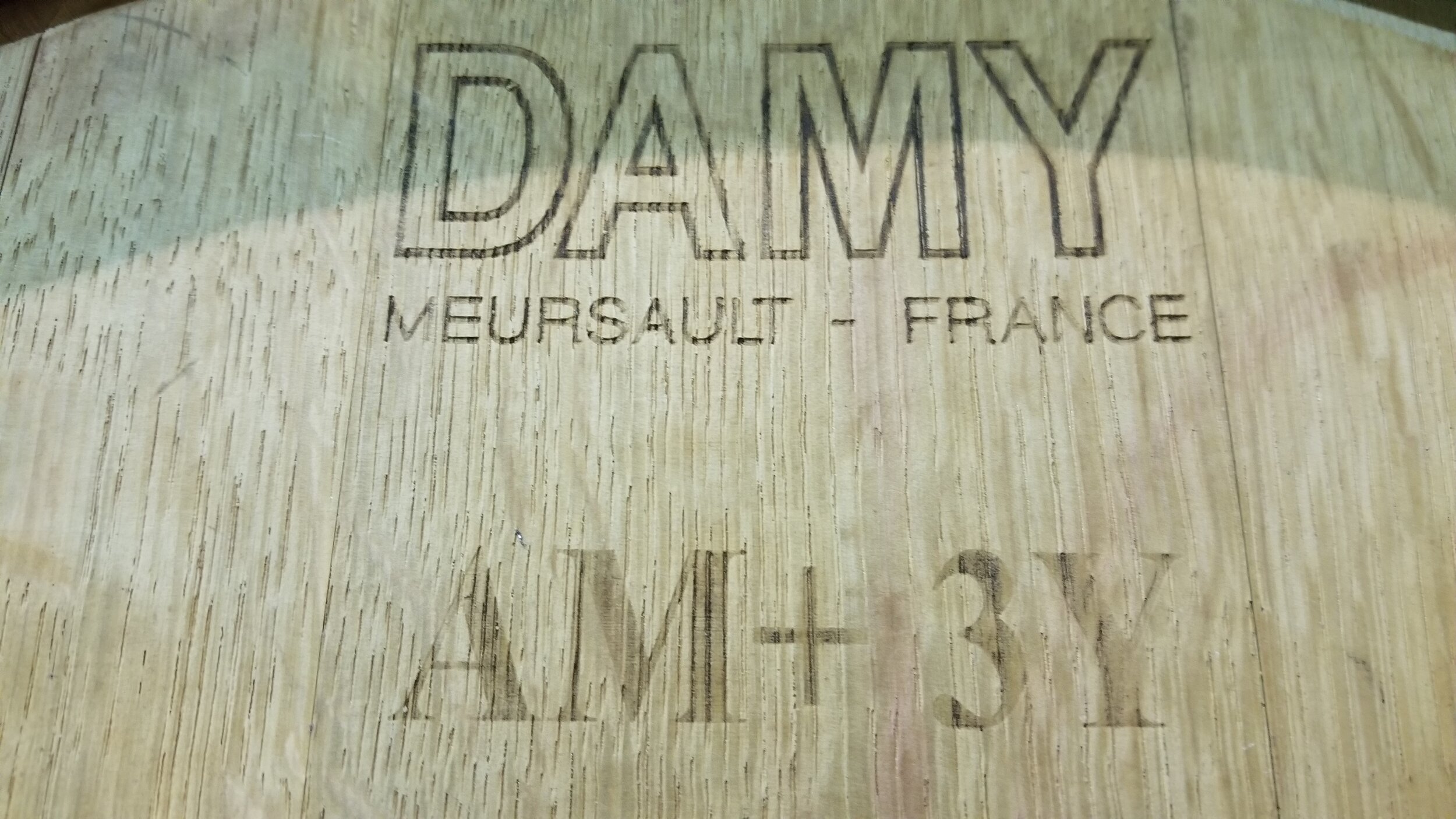

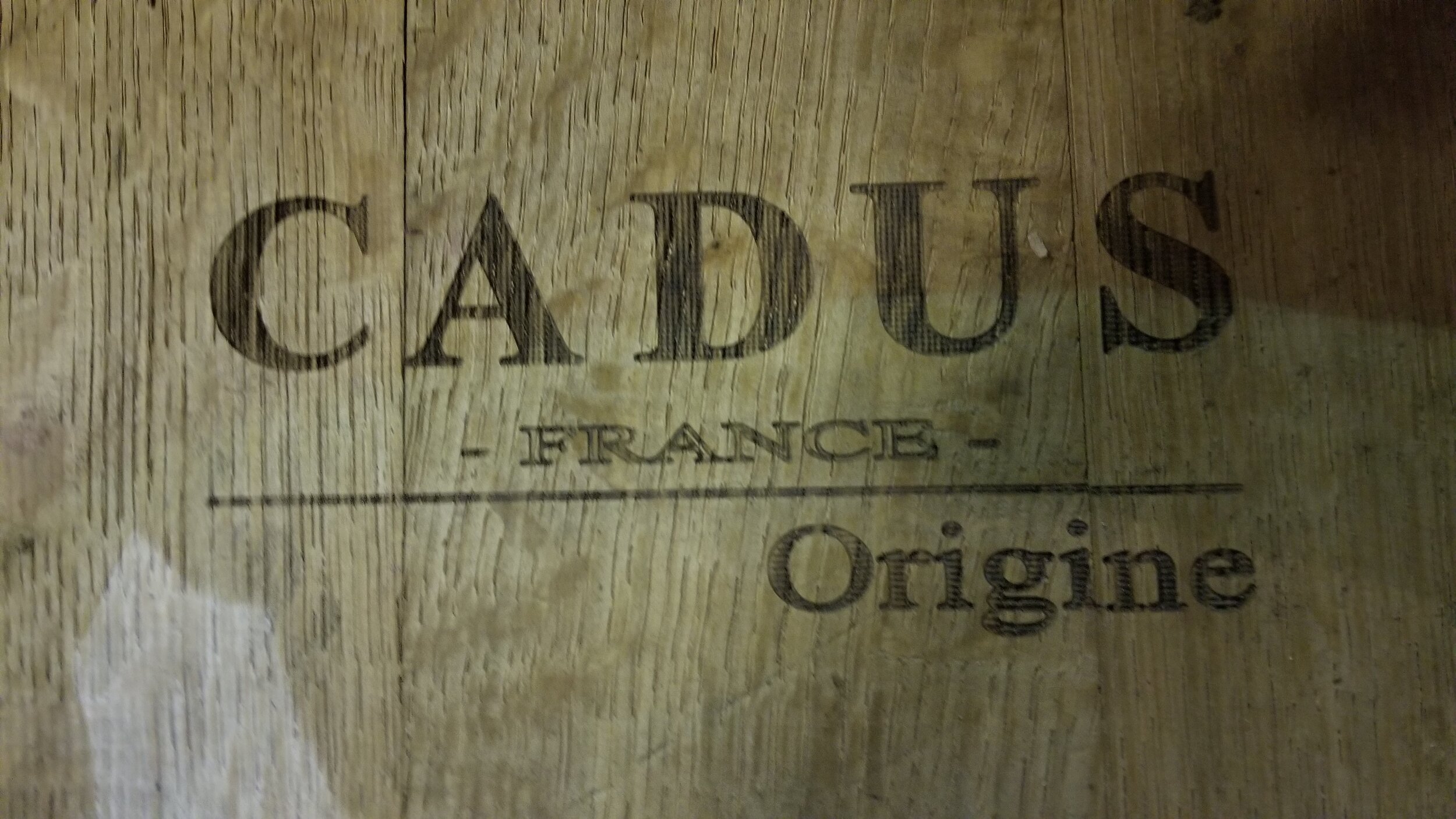

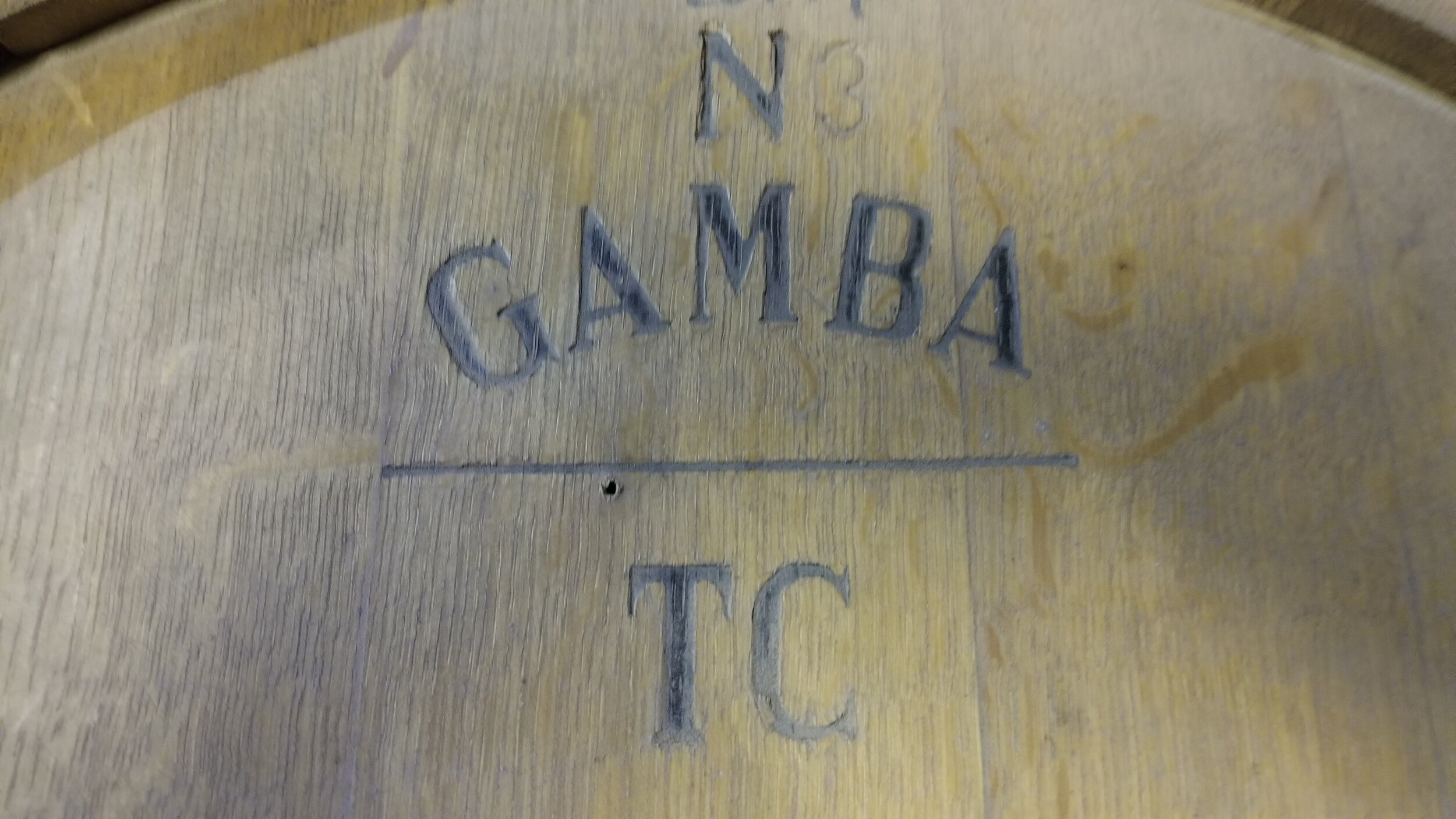

We are constantly updating our stock with neutral barrels from wineries throughout Oregon, Washington and California. In fact, many of our customers prefer our barrels over new barrels, and have build their barrel programs exclusively on Rewine Barrels. If you have a preferred cooper, region or grain structure, we will gladly work with you to sort your choices from our stock. Call, text or email anytime and we’ll get to work!